Jilin Province Wire Harness Tape Manufacturer --- Three Minutes to Deepen Your Understanding: Automatic Rubber Coating Technology for Automotive Wire Harnesses

Classification:

Industry News

Release Time:

2020-02-22

The automotive wire harness manufacturing industry is a traditional labor-intensive industry. Many basic operations, such as taping/wiring/plugging, require manual completion, resulting in low efficiency and errors. Therefore, many industry professionals are seeking ways to improve efficiency and reduce errors using machines. For example, changing the heat-shrink method from single-wire to conveyor-type, as well as automatic wire-insertion machines and automatic taping machines. Today, we will discuss automatic taping machines.

Automatic taping machines are generally divided into two categories: handheld and tabletop. Let's first look at handheld automatic taping machines. These machines are generally used in assembly line operations. The machine is suspended from a cantilever, and the operator holds the handle. The tape is fixed to the machine, and as the hand moves, the tape automatically wraps around the wire harness.

The speed of this machine can be adjusted, and the number of wraps, or tape coverage, can also be adjusted. For example, closed-type taping generally requires 30%~50% coverage, which can be seen and adjusted on the display screen; below are the images and key parameters of two common machines:

However, because it is manually controlled, the distance between the tapes cannot be automated, which is the current improvement goal for handheld automatic taping machines. Generally speaking, this type of machine is suitable for relatively simple and straight wire harnesses. For wire harnesses with too many turns and complexities (such as instrument panels and engine compartments), the efficiency is low, which is a challenge that needs to be overcome in the future.

The second type is the tabletop automatic taping machine. This machine is generally used in the pre-processing area and placed on a specific table, hence the name tabletop.

This machine, like the handheld type, can control the number of tape wraps and speed. An employee can complete the operation while sitting, which is very simple. However, as shown in the figure, it is only suitable for straight and short wire harnesses, and is not suitable for wire harnesses with multiple branches and long lengths. For batch operations, compared to operations on a fixture board, the efficiency can be greatly improved. How to make it smaller and lighter is a challenge for future development.

In addition to these two types, another automatic taping machine has also attracted attention: the automatic taping machine for parallel welding points.

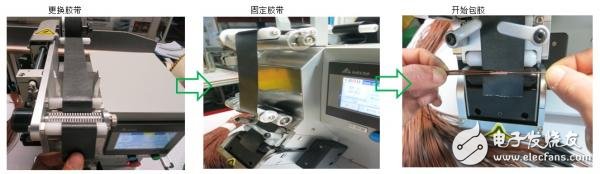

Turn on the power and replace the tape to use. It is easy to operate according to the instructions on the LCD screen.

The number of wraps and speed of the tape can be adjusted, and even the length of the tape can be adjusted. For thinner wire harnesses, the tape length can be shortened to avoid waste, while for thicker wire harnesses, it can be lengthened to ensure complete coverage.

Below is the taping process:

The efficiency is much higher than manual operation. 2.5s~3s can complete the taping of one wire harness. Theoretically, 1200 units can be produced per hour. However, the disadvantage is that it is only effective for parallel welding (double-sided) welding points, and terminal welding (single-sided) cannot be achieved for the time being. There is also an industry-wide problem: as the usage time increases, the blade will not be able to cut the tape, making it increasingly difficult to use.

The above is a brief introduction to the current automatic taping technology in the wire harness industry. This is an era of intelligence, and machines replacing manual labor is not alarmist; Jack Ma's unmanned supermarket has already been realized. How to improve efficiency further is worth considering for those in our industry.

Key words:

Car, automatic, machine, tape, can, efficiency, adjustment, use, is, for example

Contact information

Can'T Find The Product You'Re Looking For? Contact Us! To Inquire About Our Products, Please Contact Us Through The Methods On The Right And We Will Provide You With Detailed Information.

Zone 1: No. 1288, Fumin Street, Lvyuan District, Changchun City, Jilin Province

Zone 2: No. 1888, Chuangye Street, Gongzhuling Economic Development Zone, Fanjiatun Town, Gongzhuling City, Jilin Province

Quick Navigation

All rights reserved: Jilin Xiangfu Auto Parts Co., LTD